Qin Ronghua was born in the mountainous area of Yilan, Taiwan.

Dad is a lumberjack,

He has been dealing with wood since childhood.

During the Japanese colonial period,

and brought back to Japan for use.

Qin Ronghua had a knot in his heart when he was young.

"When I grow up, I must make a lot of money.

Buy all the wood in Japan."

He has a textbook struggle experience.

Qin Ronghua has worked as a cleaner and a taxi driver.

starting from the bottom of society,

In 1992, he borrowed money from his friends,

He came to the mainland alone to start a business.

27 years later, the industry has diversified into auto parts, real estate, cultural tourism, and so on.

and ranked on the Forbes list of Chinese billionaires.

After achieving success in career,

In recent years, he has established a large Japanese log factory in Jiaxing, Zhejiang Province, which has the largest number of Japanese logs in China.

From a poor boy to a billionaire,

Qin Ronghua believes that the most important thing is to not forget one's original intention.

Qin Ronghua

In August this year, Qin Ronghua met for the first time with a friend in Jiaxing, Zhejiang Province, at 5 a.m.

When most people are still asleep, this person who is on the Forbes list of the richest people in China, has already got up for work. He rarely goes to wine parties and dinners, and his daily routine is extremely regular: going to bed at eight or nine in the evening, getting up at three in the morning the next day, and starting to think and work. "You see I haven't taken a day off for 40 years, just because I have good sleep and my wife is strict with me."

As an entrepreneur, Qin Ronghua is very low-key. The private plane he bought for work needs is painted completely white without any decoration or company logo. His long-term residence in Jiaxing is located in the factory area of the enterprise, next to the staff dormitory. Every noon, he goes to the company canteen to have lunch alone. "My employees and I are a team that strives together."

As early as the early 1990s, Qin Ronghua borrowed money and traveled from Taiwan to Ningbo to start a business. He rented a dilapidated factory building of about 800 square meters and bought several pieces of equipment to start producing auto parts. At that time, Qin Ronghua was in his early thirties, without a house or car, and lived in a rented house next to the factory building, eating and sleeping with his employees.

Today, the small factory has expanded into Minth Group, a leader in the global automotive industry. "Mercedes-Benz, BMW, Rolls-Royce, Honda, Toyota... Of the ten cars running on the street now, about five are using parts supplied by us."

When the main business is developing steadily, he recalls a small goal he set when he was a child...

I was born on Taiping Mountain in Ilan, Taiwan, in 1957. I have been working with wood since I was a child. My father was a lumberjack, and until the second grade of elementary school, my family and I lived in the mountains.

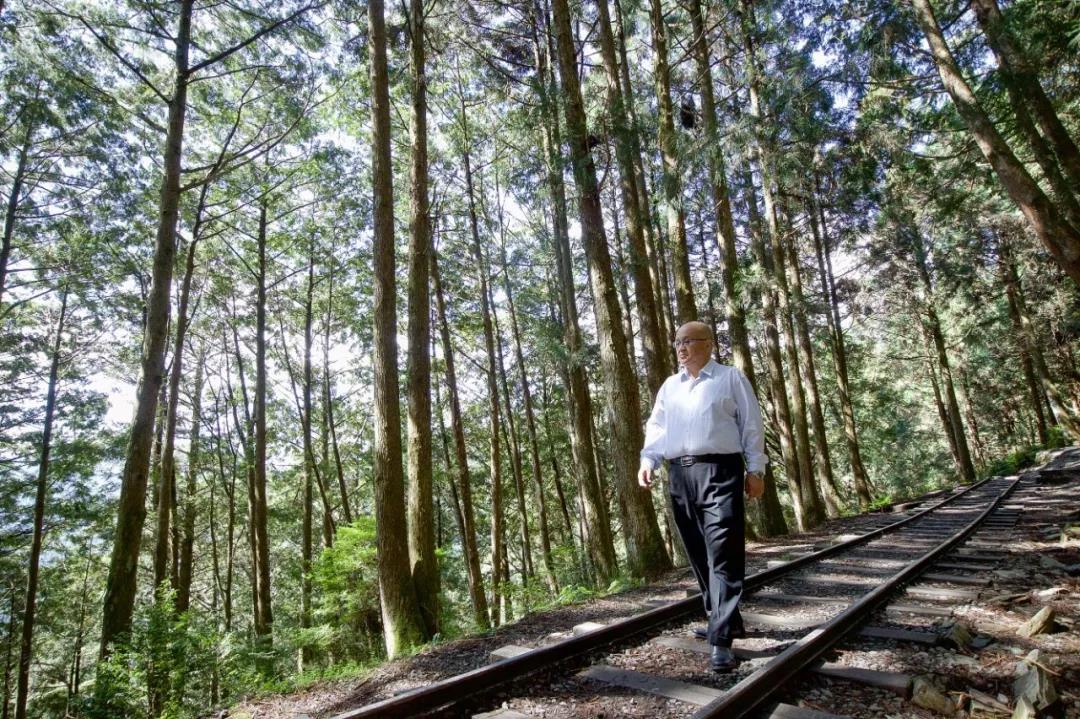

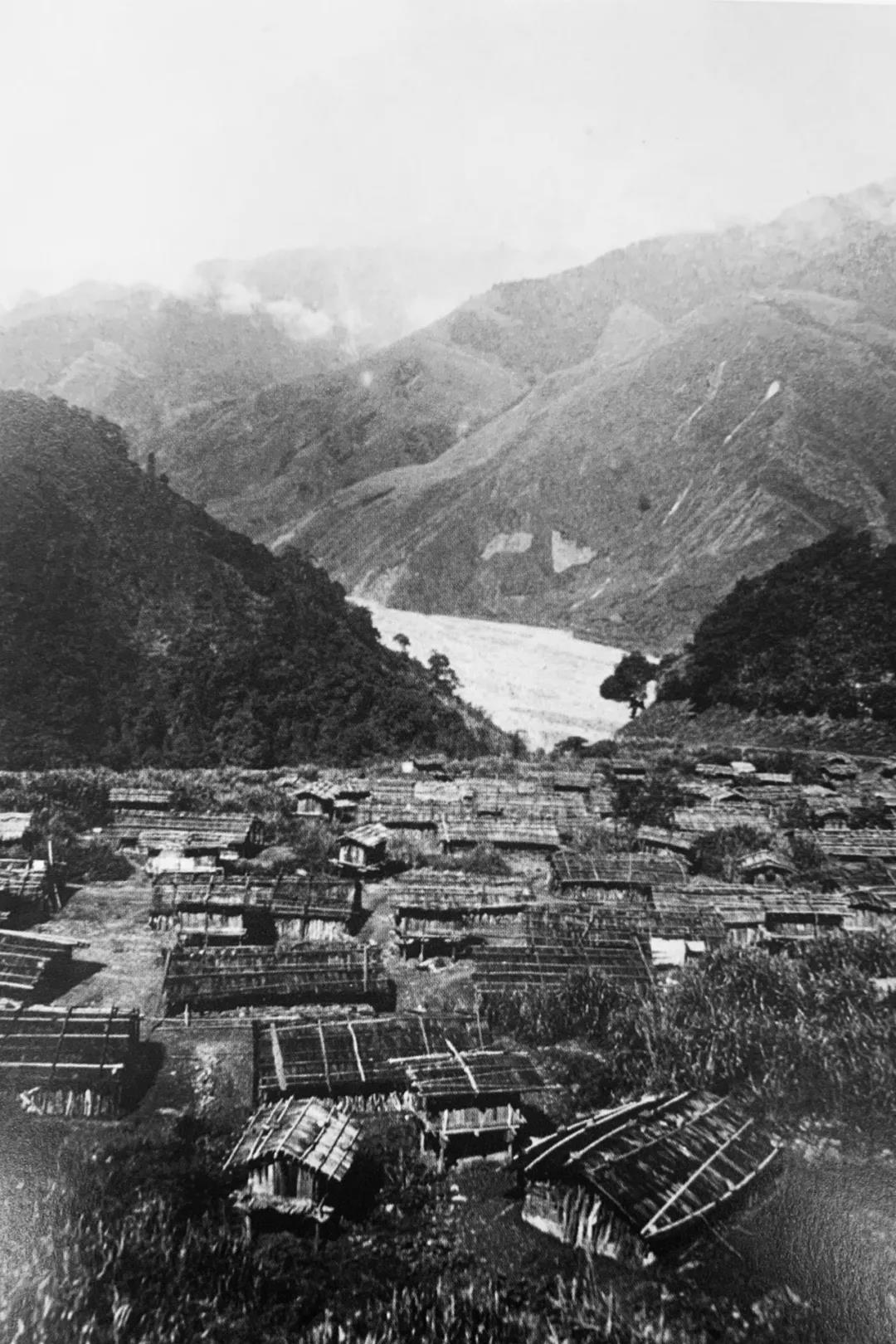

Taiping Mountain, Yilan

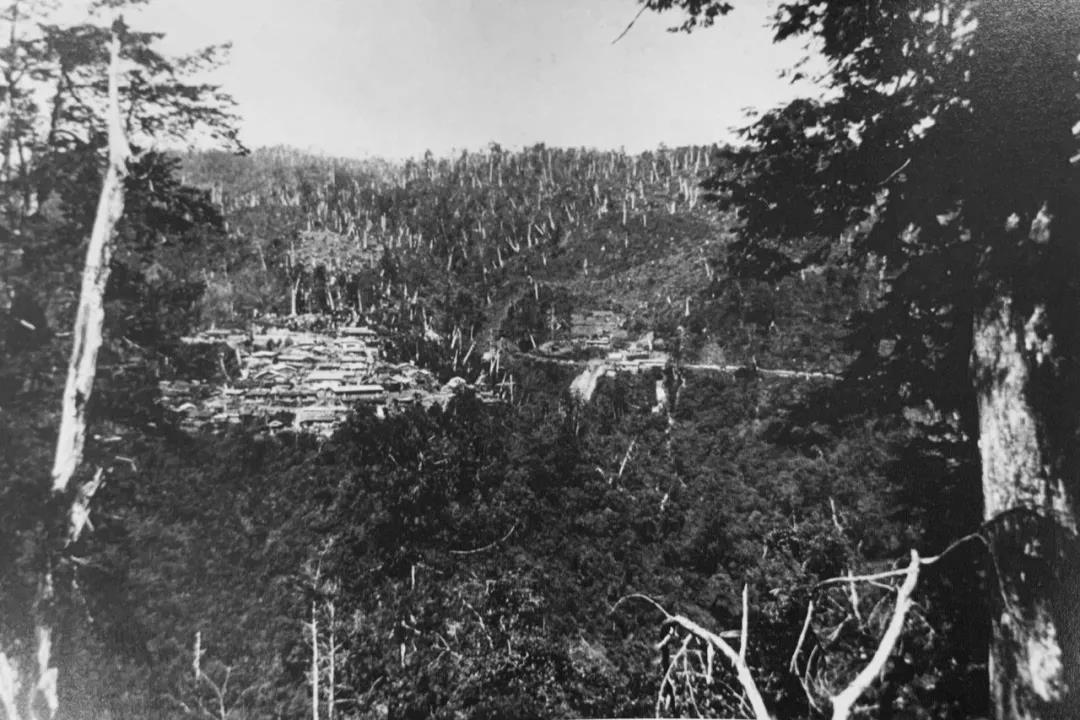

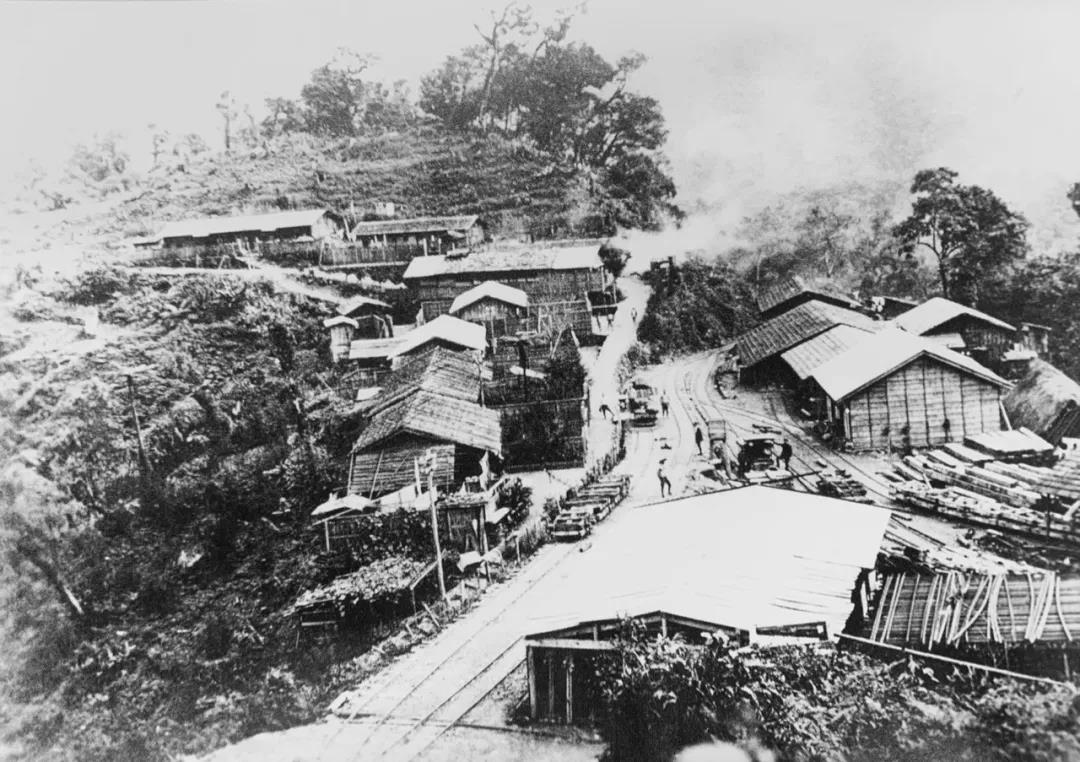

During the Japanese occupation era, Mount Taiping, Mount Ali, and Mount Baxian were collectively known as Taiwan's three major forest farms. At that time, many people made a living by logging. During the heyday, there were two to three thousand people living in Mount Taiping alone. On the mountain, our family's houses were all built of wood and were very old and dilapidated. Moreover, the whole family had to move frequently according to the location of logging. Wherever the wood was cut down, we moved there.

Old view of Mount Taiping

The houses on the mountain are all built of wood

There is no electricity on the mountain, and the only source of light at home is a kerosene lamp. However, my mother often refuses to use it, afraid of the cost of oil, so almost every day after six o'clock, as soon as it gets dark, we have to go to bed and stay asleep until dawn.

In those days, there was a shortage of materials, and people couldn't even eat enough on the mountain, let alone have any recreational activities. The only thing that excited me the most was to follow my father to the forest and watch him work from afar.

First, the loggers need to climb up to a tree that is 40 to 50 meters high and trim off all the branches. After that, they need to cut a small corner on the trunk. The angle should be aligned with the wind direction of the day, so that the tree will fall in the direction of the wind.

When a tree is about to fall, we all hide far away. With a bang, a large tree fell down, leveling the surrounding 500 to 600 square meters, which was very spectacular.

The timber cut down on the mountain will be transported to the foot of the mountain by cable car and then pulled away by train

My parents spent their whole life cutting wood and raising me. But at that time, the best wood in Taiwan was basically shipped to Japan, leaving only a little money for Taiwan. So when I was young, I already had a plan that one day I would buy wood back from Japan.

I'm in the automotive parts business, and I often have the opportunity to go to Japan. Their demand for wood has actually been saturated, so Japan is actively promoting the export of wood.

The development of timber in Japan is scientific and reasonable. They believe that from a natural perspective, if trees are systematically cut down before they become senile and young seedlings are planted to achieve renewal, the forest can develop healthier and more sustainably.

And China is the second largest timber consumer and the largest timber importer in the world, but there is a severe shortage of raw wood resources that can be used by the general public. Therefore, I came up with the idea of buying Japanese wood and bringing it back to China.

Qin Ronghua's wood factory in Jiaxing

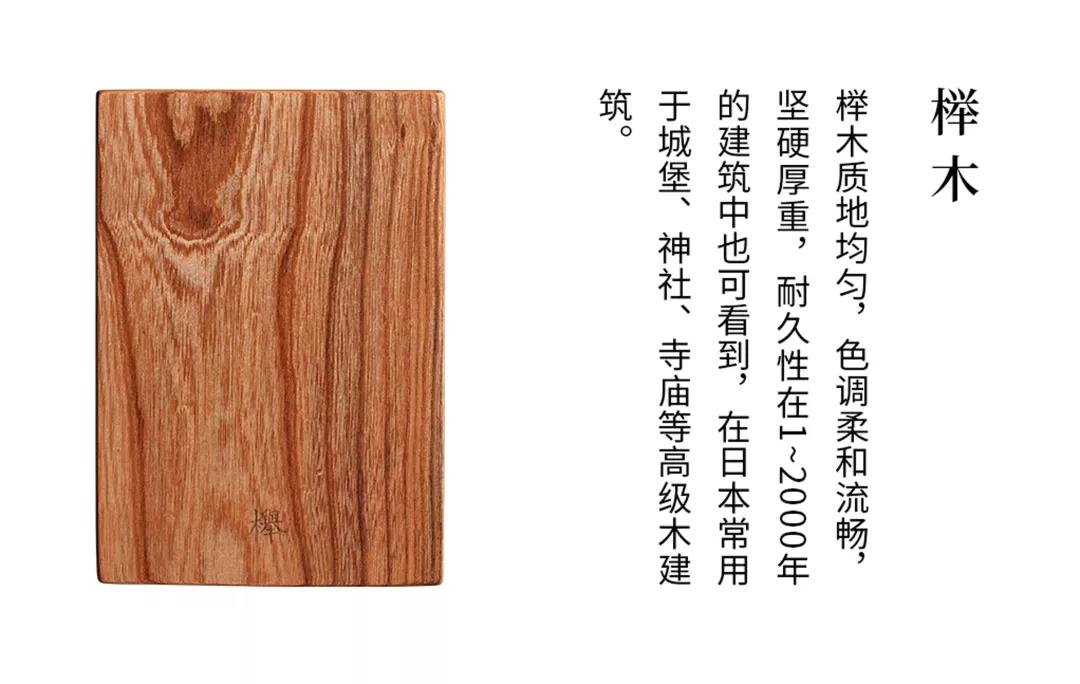

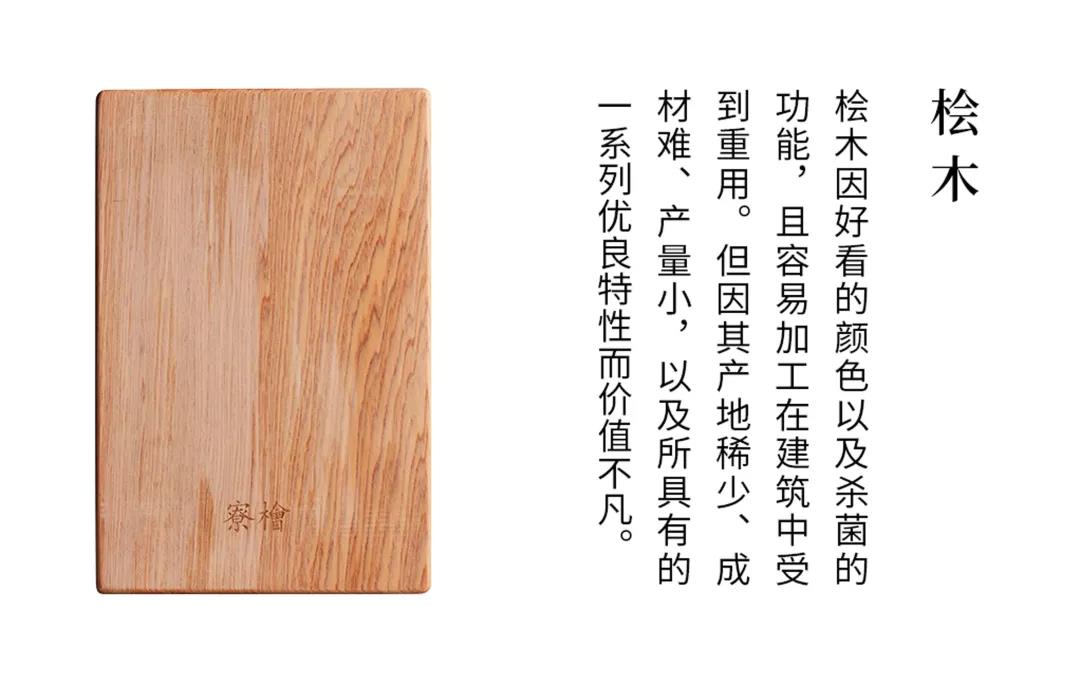

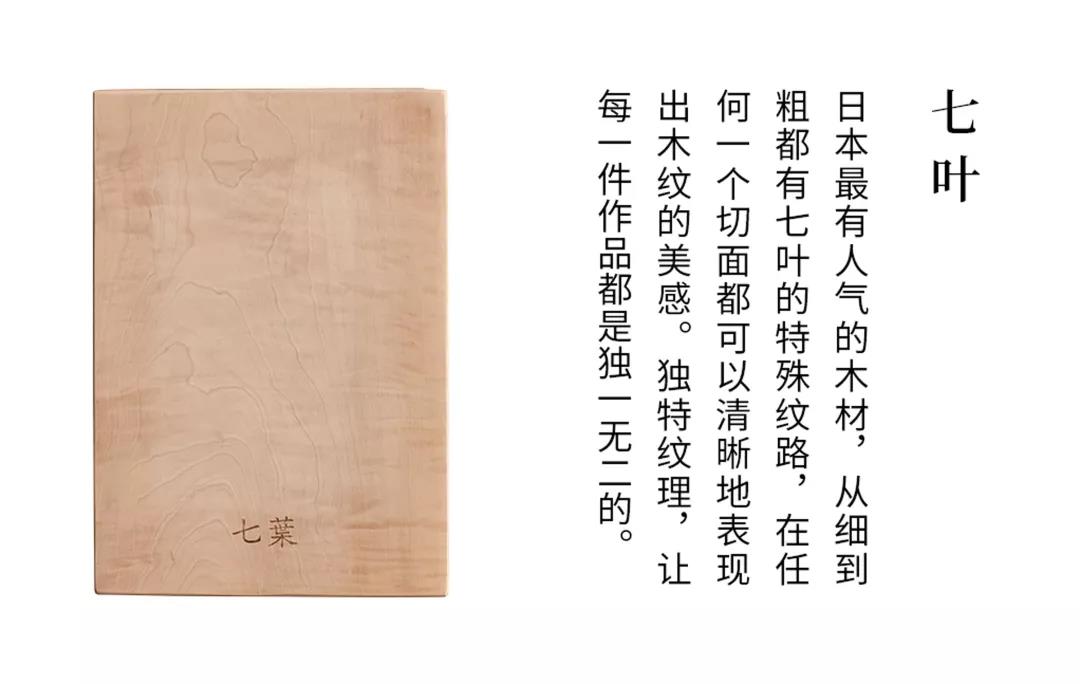

I built a wood factory in Jiaxing, Zhejiang, with an area of about 100,000 square meters and more than 10,000 logs in total. These are giant logs that have grown for more than 100 years, with diameters exceeding 1 meter, such as beech, juniper, oak, cherry, and seven-leaf maple.

Many of them are trees that fell down due to natural disasters, or street trees that died naturally on both sides of the road. We will buy them back and process and utilize them.

这里大部分的原木都来自日本,还有一些来自非洲、缅甸、老挝、柬埔寨等地。所有的木头,都是我亲自前往原产地,一根一根地挑回来的。

挑木头的过程其实很有趣,为了找到好的木材,我是一有空就全世界地跑。在日本的木材市场我算很有名了,所有人都知道我是个“木痴”,会挨家挨户找喜欢的木头。

Purchase timber in Japanese forest farm

Once I went to Gifu, Japan for a meeting. I heard that there were several very beautiful beech trees in the area. However, it was close to 12:00 am after work and I had to leave early the next day. So I had to drive overnight to the suburbs to pick up wood. At two or three o'clock in the morning, I walked with local people carrying lights in the forest for two hours to pick up the wood I wanted to buy. When we came down the mountain, it was just after 7:00 am in the morning, and we immediately rushed to the airport to catch a plane back.

I think there is no Chinese who doesn't like wood. Compared to the cold feeling of metal and cement, wood is the building material that is closest to people. Whether you sleep on it or stand on it, wood gives you a warm and friendly feeling, which is unmatched by other materials.

I prefer to call wooden appliances works rather than products, because they are truly living things that can enhance the living taste of homes. This is the charm of raw wood.

It usually takes about 10 days to transport logs from Japan to Jiaxing. All the wood will be stored in a wood factory. After design, cutting, drying, sawing, gluing, polishing, and painting, it can be made into a unique utensil or artwork, each one is unique.

I invited several master craftsmen to help me here. They are all veteran craftsmen who have been in this industry for decades. One of them was once the boss of a furniture factory. After retirement, he came to work for me and is responsible for proofing and creating. Now the old master craftsmen work together with young designers to innovate, and I often exchange ideas with them.

Furniture produced by Dajiao Wood

For all the tools, we try our best to preserve the most original aspect of the wood. The original state of the wood itself is the most beautiful, and the patterns and heaviness of the wood do not need excessive decoration.

A large table uses a whole piece of wood sliced approximately 15-20 cm thick. Although it is in use, it is still in a stockpile state for the wood, and will retain its value as it is used.

Some wood is not perfect, such as hollow, lumpy, and odd-shaped. We make unique items based on its characteristics.

For example, a table is made of camphor wood that has been exposed to 1200 degrees of lava. The traces of lava on its surface are still clearly visible, and the table also carries the unique aroma of camphor wood. We named it the "Mountain-Hugging Table".

Now, what I am doing can not only sell the Japanese timber, but also make up for China's lack of timber. The works I made are very popular with almost everyone, which can improve people's living taste. I feel that this is really valuable.

Starting from my interest, I got involved in the wood industry. My real main business is the production of automotive parts. However, before the second grade of primary school, I didn't even know what a car was.

As a child, I lived in the mountains and had never seen the outside world. I didn't even wear shoes. At that time, we were attending elementary school in the mountains, and the teachers were all former soldiers who couldn't even speak Mandarin properly.

Residential area on Taiping Mountain during the Japanese occupation era

Today's Taiping Mountain

For my future, my mother made great efforts to send me and my brothers and sisters to school at the foot of the mountain. On the day I descended the mountain, it was my first encounter with the outside world. Do you remember when I saw a military truck parked on the roadside? It was the first car I ever saw in my life, with wheels taller than our brothers! Because it's very novel, we came closer to carefully study it. The driver inside honked the horn and with a beep, both my brother and I were frightened and sat on the ground with all their might.

Father Qin Dalong (middle) is a lumberjack

My father passed away in a work accident. Due to the family's poverty, I experienced much more than other peers during my school years.

The lighting in my home was all based on kerosene lamps, which made it very inconvenient for reading and writing. I became nearsighted when I was young. Once my glasses broke a lens, but I didn't have enough money to replace it. So when I was in class, I would squint one eye and only use the lens side to see the blackboard. This lasted for a while. Later, a young geography teacher came to the school. She saw me like this and called me aside and handed me some money to replace the lens. This was the best thing that happened to me when I was young. From that day on, I got 100 points in every geography exam.

Yilan Gongzheng Primary School where Qin Ronghua studied

After 40 years, I took my wife and inquired for a long time, finally finding my geography teacher in the countryside of Ilan. I really appreciate her help to me back then.

Of course, there are also things that make me upset. Every Wednesday, there is an art class, and students are required to bring watercolors to class. However, my family doesn't have the money to buy them for me. So every time I go to class, I have to tell the teacher that I forgot to bring them. The teacher will then make me put out my hand and hit my palm with a ruler for 10 times as punishment. So I definitely can't sleep on Tuesday night, because I'm always afraid that the teacher will hit me the next day, which really hurts.

Qin Ronghua in her youth

When I was a child, my dream was very simple and clear, which was to find ways to make money quickly and improve the life of my family.

When I was young, I hardly slept. In order to make money, I did a lot of jobs. When I was sixteen or seventeen years old, I started classes at nine in the morning, then went to a welfare institution as a work-study student to clean up. At night, I would drive a taxi until ten or so and then go to school until five in the morning. During class, I would doze off. This kind of life continued day after day for three and a half years.

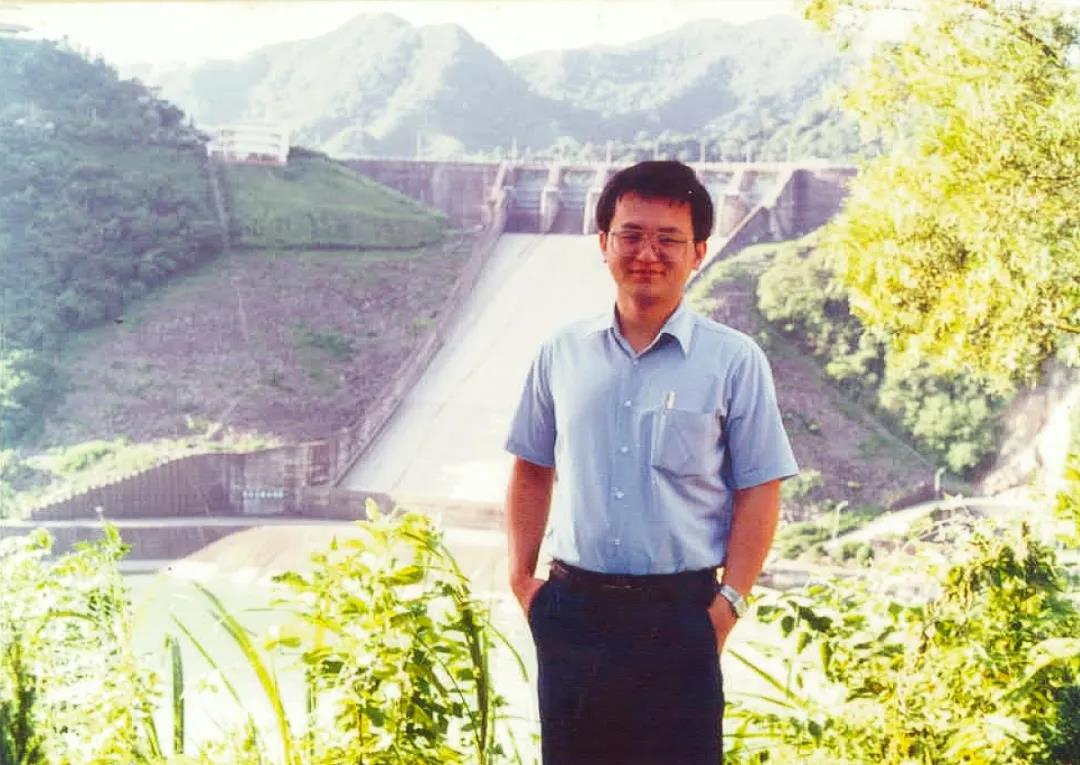

Qin Ronghua's office in Ningbo factory

After graduation, I found a job in Taiwan where I could live relatively stable, but I wasn't willing to settle. At that time, my father-in-law was in the automotive parts industry, and he introduced me to this business. In 1992, I borrowed money from friends and banks and went to Ningbo to start my own business.

It was definitely very tough at the beginning. We had nothing, starting from scratch. I recruited about 20 young people locally, rented a factory building, bought several sets of equipment, and started production.

I lived in a rented house with my employees back then, eating and sleeping with them. It was very cold in Ningbo in winter, and the house we lived in was a mud hut, with walls that let in air. Of course, there was no heater, so every night we had to prepare several warm waterbags and put them on our feet to keep warm.

Sometimes when it's too cold to sleep, I'll go to the duty room of the neighboring government agency and chat with the personnel on duty until dawn.

Qin Ronghua (first from the right) in Japan

We started with orders for domestic cars, and then tried to expand into the business of large car brands. Back then, we were a small factory and it was very difficult to win big orders. When we tried to cooperate with large foreign factories, they didn't take us seriously and weren't even willing to come and inspect our factory.

I really tried everything to win orders. In the early 1990s, it cost 300,000 yuan to buy a car in Ningbo, but only 90,000 yuan to buy a house. But I dared to spend 70,000 yuan to rent a plane for one day to grab orders. I still remember that I chartered a business jet and used it to fly Japanese partners to Ningbo for one day to visit our factory and discuss cooperation with them. Afterwards, I sent them back to Japan by plane that night.

In 1993, I dared to do it. However, it turned out that I succeeded. In the first year, I made a business of 3 million yuan. In the second year, our revenue began to grow rapidly. Then step by step, I built my career.

Today's Minth Group

At present, we have 40 factories worldwide with more than 10,000 employees. About five out of ten cars on the road use our products.

By the standards of the public, I should be considered somewhat successful in the automotive parts industry. Now I have the ability to engage in the wood industry that I have longed for.

Actually, the most important thing is not to forget our original intention when doing anything. I want to hand my logs over to the right people, and to have more conscientious craftsmen join us and give the logs a second life. This is what I want to do most now.

Dajiao Wood will not forget its original aspiration and forge ahead!